How to keep fire away in summer?

First, fire-proof

1, hot summer, high temperatures. In the chemical production area, flammable, explosive, volatile raw materials more. For example: ethanol, dichloroethane and other low boiling point, are volatile substances. In the hot summer volatilization faster, in the relatively high concentration of places can easily reach its ignition and explosion limit.

2, the summer is either a thunderstorm, or hot and dry, when the air is dry, the more attention should be the importance of fire. For the characteristics of the summer chemical production and the nature of the raw materials used, we must first pay attention to fire. To seriously abide by the relevant provisions of the post operators to seriously operate, strictly eliminate the "three violations" phenomenon; the duty inspectors should be carefully checked and found that fire or violation of discipline should be dealt with severely.

KOUDX's safety cabinets are widely used in automotive manufacturing, petrochemical, industrial manufacturing, laboratory, food industry, power industry, new energy and other fields.Safety Cabinet gets CE certificate; Accord with(OSHA) OSHA 29 CFR 1910.106 & (NFPA) NFPA CODE 30.

Second, anti-poisoning

Many of the raw materials of chemical companies are toxic or corrosive, inadvertently in contact with or inhalation of toxic substances or these substances volatile gases can cause varying degrees of poisoning or cause physical damage, severe cause even burns or even coma or death. Especially in the summer, the weather is hot, the staff wear relatively thin, in the working state and relatively easy to sweat. The hot weather, toxic and hazardous substances very volatile, volatile toxic gases through the pores of the human body into the body caused by poisoning.

Therefore, to understand the nature of the contact with the material and the corresponding precautions is particularly critical, once these toxic and hazardous substances splashed on the body, immediately rinse with water, and replace the clean clothes, hand observation and supervision, serious to the hospital for treatment

Third, anti-leakage

In the summer production, once the raw material leakage, not only caused environmental accidents and material losses, and the most likely to cause poisoning, especially the leakage of materials directly splashed on the operator (or even mouth), more dangerous ( Once these toxic and hazardous substances splashed on the body, immediately rinse with water, and replace the clean clothes, there are special observation and supervision, serious to the hospital for treatment).

To prevent leakage, should do the following:

1, careful operation: the material delivery valve and pipe disassembly or connection, etc. must pay attention to whether the closure is closed, the opening is open. To prevent leakage of material on the outside or local pressure and lead to leakage caused by leakage.

, some glass mirror, vent valve (mouth), level gauge and switch valves must have protective measures to prevent collision, error or damage caused by the occurrence of leakage accidents.

3, the tank level of strict control in the standard (warning) line, strict wire storage to prevent the overflow. At the same time, be sure to regularly check and verify the accuracy of the tank level gauge, in order to avoid false liquid level or cause false objects caused by flash.

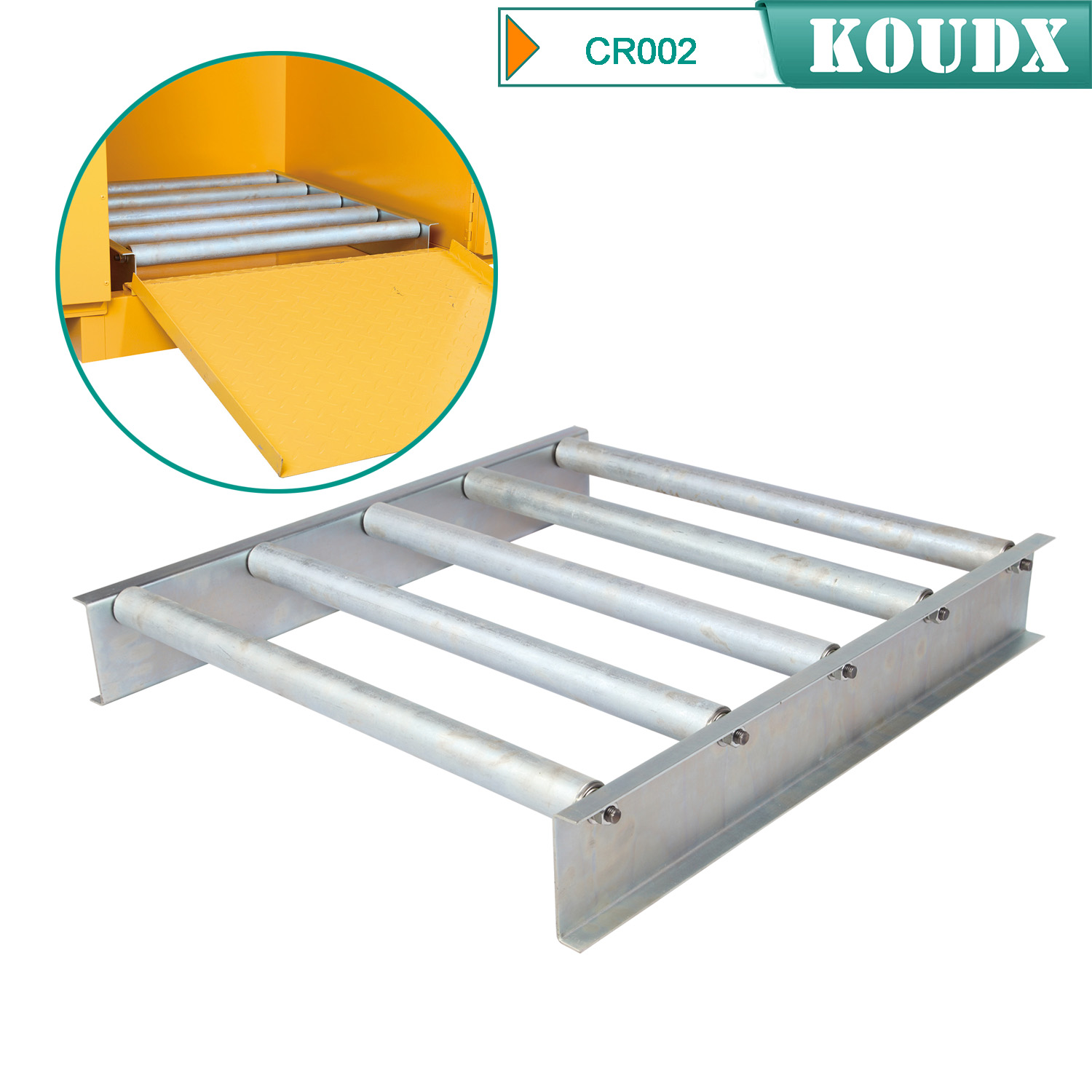

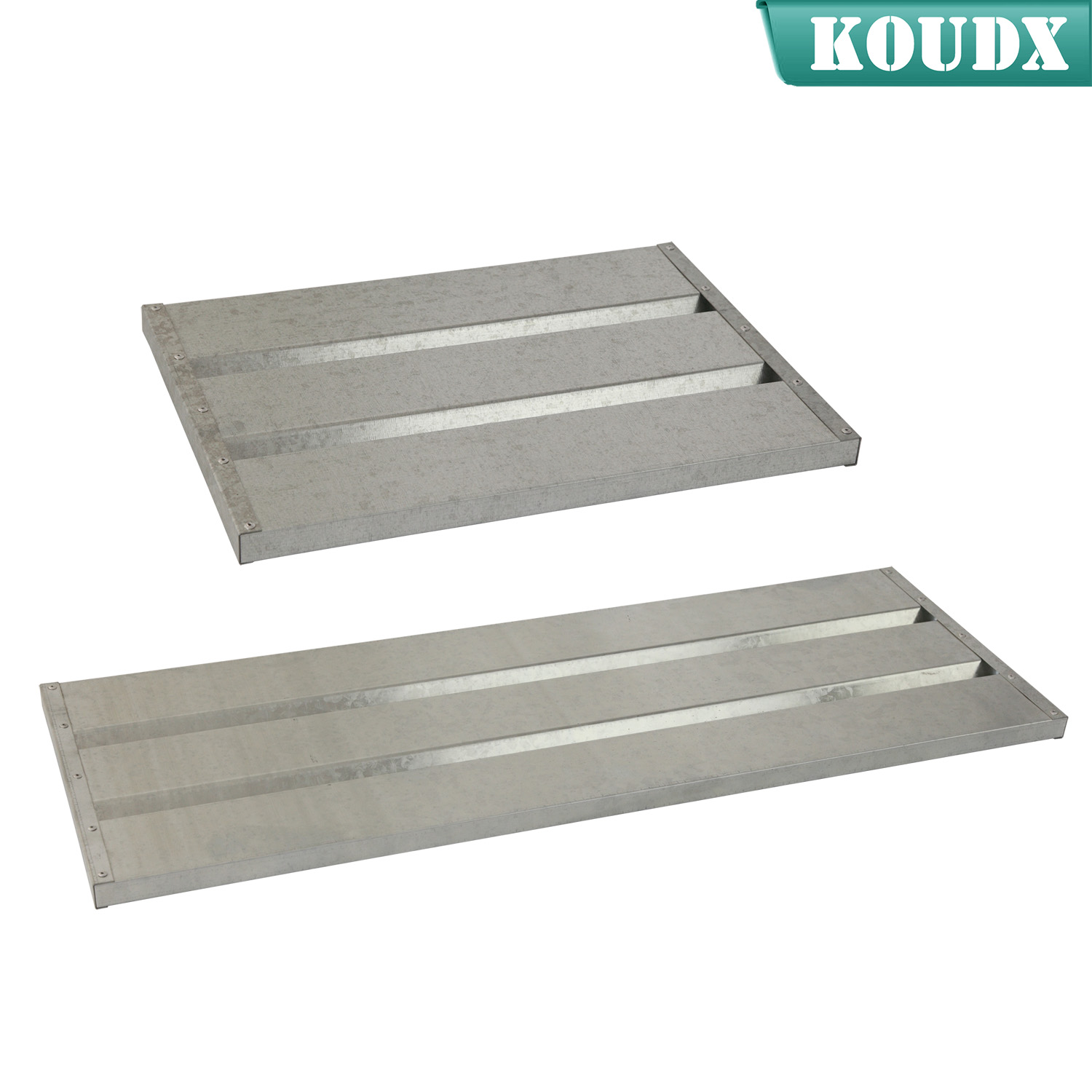

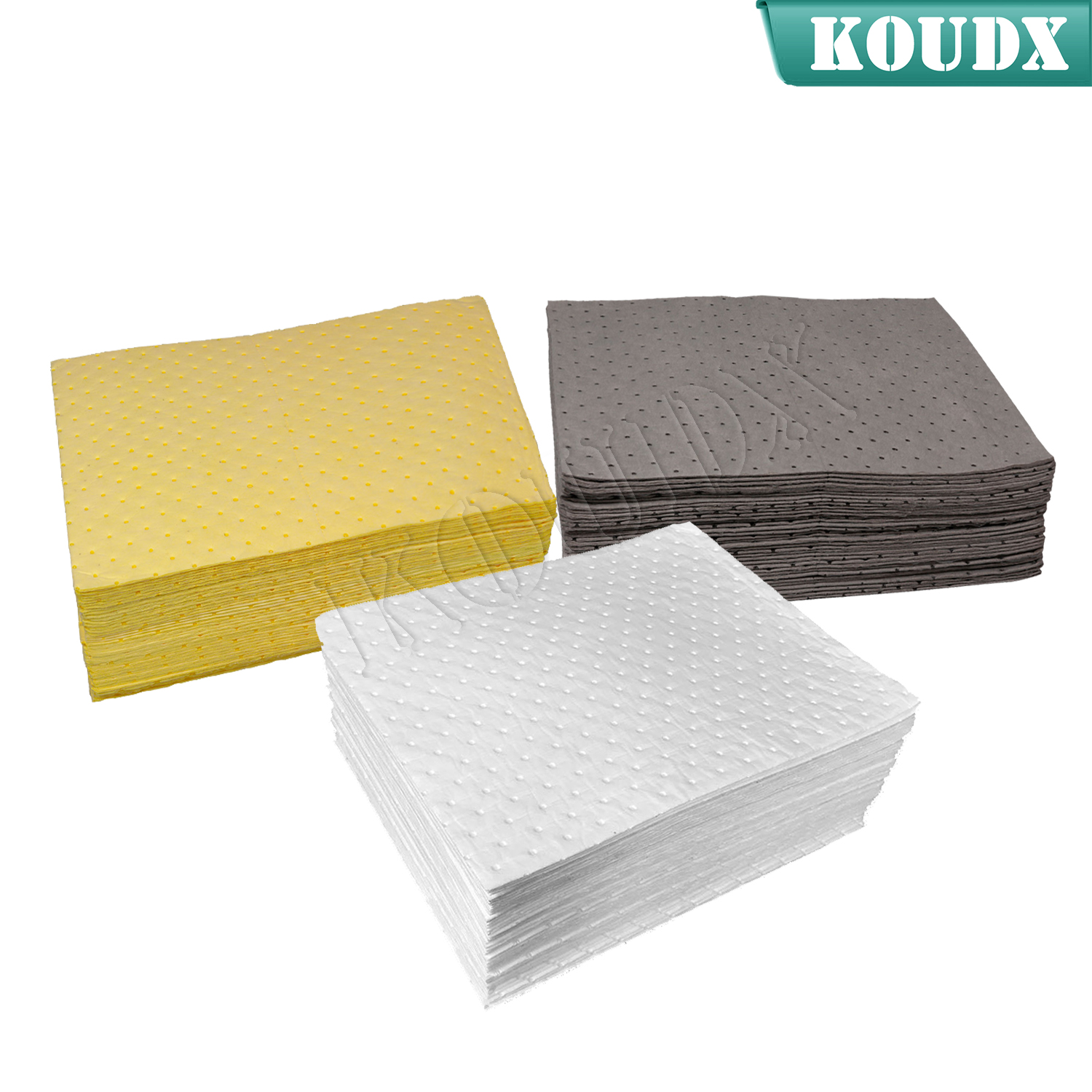

The KOUDX spill pallets of the US Environmental Protection Agency (EPA) and the US National Pollution Abuse Prevention System (NPDES) have a unique role in handling leakage of materials and control the development of leaks.

KOUDX supply high quality spill control products, protect for the employees and environment. We have various models for your choice.

Fourth, anti-explosion

Chemical enterprises use a lot of raw materials with flammable and explosive, toxic and other characteristics, and the reaction is complex; in addition to good anti-poisoning, anti-over-temperature, anti-leakage and other basic prevention, the most important one is to do anti- This is the most dangerous and in the event that the most dangerous process will occur with fire, leakage, poisoning and environmental pollution.

Therefore, anti-explosion is the most critical security precautions:

1, to strengthen the safety valve, explosion-proof membrane, distillation system, such as supervision and management, monitoring. Periodic inspection, inspection or replacement, always make it in a good working condition, should be treated as a special safety monitoring point.

2, careful operation, is strictly prohibited to violate the operating procedures and prohibit overrun operations, so as to avoid inadvertently, check not in place and leakage, pressure, over-temperature overpressure, static electricity or replacement, etc. These can cause serious explosion , To the casualties and corporate property caused great losses.

3, to strengthen the fire source management, is strictly prohibited fire into the production area, is strictly prohibited to prevent illegal fire operations and to prevent the burning of inflammable and explosive substances and explosion.

4, is strictly prohibited the reaction of the two items mixed with the heat generated by burning or explosion. Therefore, the warehouse and the workshop once to strengthen this management, is strictly prohibited should not be mixed with the items stored in the warehouse.

Five, anti-shock

Hot weather, the distribution of indoor temperature is relatively high, electrical equipment damage, aging, failure and other factors affect the production of electricians in the process of strengthening inspection inspection, must strictly guard against, protection and supervision, can not have any paralysis and Lucky.

1, electrical duty on duty during the period must wear the necessary labor protection equipment, and must wear anti-insulated shoes, maintenance wear insulated gloves, the key maintenance parts to do one person overhaul supervision, and always do a good job protection and preventive measures.

2, electrical instrument maintenance and operation of equipment maintenance operations must first power off, hang up "is operating, forbidden closing" eye-catching signs, in the relevant personnel under the conditions of monitoring, before the maintenance work. Forbidden because of robbing time, rush to the degree of illegal operations and illegal command, resulting in accidents.

3, the various departments (production positions) operators are not in charge of electrical appliances, instruments, buttons and other charged facilities can not move, their own in charge of the failure immediately after the report on a leadership, notify the electrical maintenance process maintenance personnel, is strictly prohibited , Demolition and maintenance and other illegal acts.

4, electrical instrument maintenance must be in accordance with the maintenance procedures, norms for operations. It is strictly forbidden to cut the road, with non-standard, models do not match the accessories instead of regular and standardized accessories to make do or find over-temperature, overrun and overdue work of electrical instrument work.

5, to strengthen the duty inspection, duty period to do a comprehensive, detailed and standardized, and do the shift record. Especially in the face of bad weather or thunderstorms to strengthen the intensity of the workshop of the electrical instrument of the rain, lightning protection facilities to seriously check, emphasize and arrange to prevent the impact of production or cause electric shock.

KOUDX Safety Cabinet is used for the storage of flammable liquids, chemicals, combustibles, toxic substances and pesticides, etc. It is widely used in the workshop of the factory, hospitals or laboratories in universities.The application industries include Oil, Gas, Power, Chemicals, Firefighting, Automobile, Laboratories, Electronics, Warehouse, Telecommunications, Marine, Cosmetics and Food, etc.

KOUDX(Shanghai Koudx Industry Technology Co., Ltd.) is a professional provider of industrial safety and environmental protection solutions. Based on the concept of market and customer demand, our fire safety cabinet was developed in accordance with the standards of OSHA 29 CER 1910.106 and NFPA CODE30. It is widely used in petrochemical industry, industrial manufacturing, university laboratories, food industry, automobile industry manufacturing, new energy and other industries.

We sincerely hope that in the journey of KOUDX's continuous development and expansion, we will be able to get the full support of our distributor partners in China and abroad, and have more long-term strategic partners, development together and achieve a win-win situation. Welcome to contact us (86) 400-168-8090, you can visit our website www.koudx.com for the detail information.