Chemical storage cabinets, whether used for flammables, corrosives or pesticides/poisons, often come with capped bung openings that allow for ventilation. While cabinet manufacturers may provide the bungs for ventilation purposes, venting flammable liquid storage cabinets is NOT required or even recommended by any federal regulatory agency. Cabinet manufacturers include venting bungs for users who may be required to vent by state or local codes, individual company policies, insurance carrier policies or any other authority having jurisdiction (AHJ).

Don't Vent Unless You Have To

According to the National Fire Protection Association (NFPA) Code 30, Flammable and Combustible Liquids Code, venting a flammable storage cabinet is not necessary for fire protection purposes. Flammable and combustible liquid storage cabinets are designed to help protect the internal contents from a fire outside of the cabinet. A vented cabinet could compromise the ability of the cabinet to protect its contents from a fire.

NFPA 30, 9.5.4 states, “Storage cabinets shall not be required by this code to be ventilated for fire protection purposes.” Additionally, in Annex A, NFPA offers further reinforcement that venting is not necessary. A.9.5.4 states, “Venting storage cabinets has not been demonstrated to be necessary for fire protection purposes. Additionally, venting a cabinet could compromise the ability of the cabinet to adequately protect its contents from involvement in a fire because cabinets are not generally tested with venting. Therefore, venting of a storage cabinet is not recommended.”

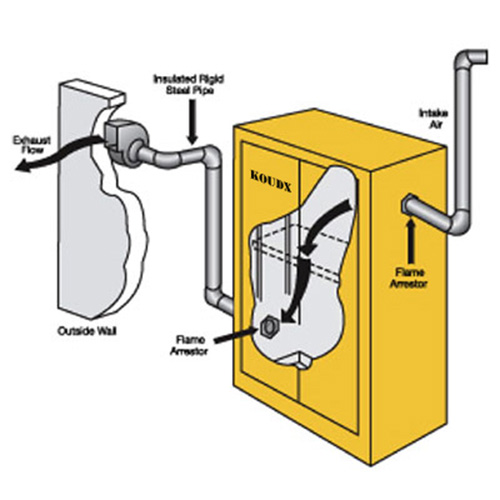

If venting is being considered, 9.5.4.2 addresses some minimal design requirements. It states, “If a storage cabinet is ventilated for any reason, the vent openings shall be ducted directly to a safe location outdoors or to a treatment device designed to control volatile organic compounds (VOCs) and ignitable vapors in such a manner that will not compromise the specified performance of the cabinet and in a manner that is acceptable to the AHJ.” If the cabinet is not vented, the NFPA code requires that the bung caps remain sealed as 9.5.4.1 states, “If a storage cabinet is not ventilated, the vent openings shall be sealed with the bungs supplied with the cabinet or with bungs specified by the manufacturer.”

While not federally mandated, state or local AHJ may require venting. NFPA 30 acknowledges this under A.9.5.4 where it states, “However, it is recognized that some jurisdictions might require storage cabinets to be vented and that venting can also be desirable for other reasons, such as health and safety.”

How Do I Know If I Need to Vent My Flammable Storage Cabinet and How Is It Done?

As it’s clearly indicated above, from a federal regulatory compliance perspective there is no requirement to vent a cabinet. To determine if additional regulations or requirements apply to your specific situation, you’ll need to confer with your AHJ.

Should you learn from your AHJ that ventilating your flammable storage cabinet is a requirement, be sure to obtain clear and detailed instructions as to how the cabinet needs to be vented. They should not only supply the “how” but also specific requirements for the equipment needed to mechanically vent the cabinet.

NFPA 30 does offer additional venting guidance should the AJH deem it necessary. Under A.9.5.4.2 it states:

“A “safe location” should be selected as the location of a vent discharge to minimize the potential for ignitable vapors to travel to a source of ignition after discharge from the vent. Electrical equipment that does not meet the requirements for hazardous locations can serve as an ignition source. The Technical Committee advises that vent discharge locations should consider such factors as the following:

-

Characteristics of the exhausted material (vapor density, toxicity, velocity of discharge, etc.)

-

Proximity to potential ignition sources

-

Building openings such as doors, windows, air intakes and so forth

-

Dispersion characteristics (distance to discharge within the flammable range, direction of discharge, atmospheric conditions, and the influence of building and neighborhood buildings on discharge vapors)

-

Likelihood of vapor accumulation following discharge, such as an accumulation under building eaves

-

Likelihood of sufficient discharge volume to allow an ignitable concentration to reach an ignition source

Historically, NFPA 30 has provided prescriptive guidance, often based on area classification requirements, and results have been acceptable. Closer distances should be accepted only if an analysis by a qualified person justifies closer distances. Similarly, the specified distances might not be acceptable for all installations, thus the guidance provided above.”

Again, these are general guidelines taken from current NFPA references. Your AHJ that’s requiring you to vent is the ultimate authority regarding how the cabinet must be vented.

The above NFPA guidelines refer specifically to flammable liquid storage cabinets; if, at the request of your AHJ, you’re required to vent a corrosives/acid cabinet, make sure to incorporate a blower that’s compatible with the vapors being exhausted. Also be aware that if it’s a hazardous material you’re venting, you may not be allowed to exhaust to the outside due to the health hazards the vapors present.

For more information on chemical storage in the workplace, see Quick Tips #181: Chemical Compatibility Concerns in Storage. For additional information on flammable liquids in the workplace, see Quick Tips #179: Flammable Liquids and Quick Tips #180: NFPA 30: A Guide to Flammable Liquids.

Commonly Asked Questions

Q. What is a flame arrestor?

A: A flame arrestor is a special fine metallic screen that helps prevents backflow or flashbacks of flames. Designed to allow liquids and vapors to pass through, it provides a barrier to flame passage if the vapors on either side should ignite.

Q. Are there any options short of venting to control the levels of vapors inside flammable and chemical storage cabinets?

A: Inserts are available for storage cabinets that contain activated carbon to aid in lowering the levels of VOCs or corrosive vapors inside the cabinets.

Q. Do I need self-closing doors?

A: Self-closing doors are not a federal requirement; however, some states and/or local municipalities do enforce the International Fire Code (IFC) or the NFPA 1 Fire Code which does mandate self-closing doors. To find out if you are in an area that requires self-closing doors, contact your local fire marshal or AHJ.

KOUDX(Shanghai Koudx Industry Technology Co., Ltd.) is a professional provider of industrial safety and environmental protection solutions. Based on the concept of market and customer demand, our fire safety cabinet was developed in accordance with the standards of OSHA 29 CER 1910.106 and NFPA CODE30. It is widely used in petrochemical industry, industrial manufacturing, university laboratories, food industry, automobile industry manufacturing, new energy and other industries.

We sincerely hope that in the journey of KOUDX's continuous development and expansion, we will be able to get the full support of our distributor partners in China and abroad, and have more long-term strategic partners, development together and achieve a win-win situation. Welcome to contact us (86) 400-168-8090, you can visit our website www.koudx.com for the detail information.