IntroductionAlmost all fires are small in their incipient stage and can be put out quickly if the proper firefighting equipment is available and the person discovering the fire has been trained to use the equipment at hand. Most facilities turn to portable fire extinguishers for fighting incipient stage fires. The requirements for portable fire extinguishers in general industry are governed by the Occupational Safety and Health Administration (OSHA) and are located in 29 Code of Federal Regulations (CFR) 1910.157.

To be effective, according to OSHA, portable fire extinguishers must be:

Approved by a recognized testing laboratory; extinguishers manufactured in the U.S. are generally approved by FM Global and listed by Underwriters' Laboratories, Inc. (UL))

Of the proper type for the class of fire expected

Located where they are readily accessible for immediate use and in sufficient quantity and size to deal with the expected fire

Inspected and maintained on a regular basis so that they are kept in good operating condition

Operated by trained personnel who can use them effectively

Classification and Use

Underwriters’ Laboratories classifies fire extinguishers by the type of fire that they will extinguish.

Class A fire extinguishers are used for ordinary combustibles such as wood, paper, some plastics and textiles. This fire class requires the heat-absorbing effects of water or the coating effects of certain dry chemicals. Extinguishers suitable for Class A fires should be identified by a triangle containing the letter “A.” If in color, the triangle should be green.

Class B fire extinguishers are used for flammable liquid and gas fires such as oil, gasoline, etc. These fire extinguishers deprive the fire of oxygen and interrupt the fire chain by inhibiting the release of combustible vapors. Extinguishers suitable for Class B fires should be identified by a square containing the letter “B.” If in color, the square should be red.

Class C fire extinguishers are used on fires that involve live electrical equipment that require the use of electrically nonconductive extinguishing agents. Once the electrical equipment is de-energized, extinguishers for Class A or B fires may be used. Extinguishers suitable for Class C fires should be identified by a circle containing the letter “C.” If in color, the circle should be blue.

Class D fire extinguishers are used on combustible metals such as magnesium, titanium, sodium, etc., that require an extinguishing medium that does not react with the burning metal. Extinguishers suitable for Class D fires should be identified by a five-point painted star containing the letter “D.” If in color, the star should be yellow.

Class K fire extinguishers are used on fires involving cooking media (fats, grease and oils) in commercial kitchens. Due to the higher heating rates of vegetable oils in commercial cooking appliances, the National Fire Protection Association (NFPA) Standard for Portable Fire Extinguishers (NFPA 10) includes a Class K extinguisher. These fire extinguishers work on the principle of saponification, which takes place when alkaline mixtures such as potassium acetate, potassium citrate or potassium carbonate are applied to burning cooking oil or fat. The alkaline mixture combined with the fatty acid creates a soapy foam on the surface that holds in the vapors and steam and extinguishes the fire. These extinguishers are identified by the letter K.

Labeling

Portable fire extinguishers are labeled so users can quickly identify the classes of fire on which the extinguisher will be effective. The marking system combines pictographs of both recommended and unacceptable extinguisher types on a single identification label. Following are examples of typical labels.

Extinguisher for Class A, B and C

Extinguisher for Class B and C

Extinguisher for Class A and B

Extinguisher for Class A

Also located on the fire extinguisher label is the UL rating, which is broken down into Class A and Class B:C ratings. These numerical ratings allow you to compare the relative extinguishing effectiveness of various fire extinguishers. For example, an extinguisher that is rated 4A:20B:C indicates the following:

-

The A rating is a water equivalency rating. Each A is equivalent to 1.25 gallons of water. 4A = 5 gallons of water.

-

The B:C rating is equivalent to the amount of square footage the extinguisher can cover, related to the degree of training and experience of the operator. 20 B:C = 20 square feet of coverage.

-

C indicates it is suitable for use on electrically energized equipment.

When analyzing these ratings, note that there is not a numerical rating for Class C or Class D fires. Class C fires are essentially either a Class A or Class B fire involving energized electrical equipment where the fire extinguishing media must be non-conductive. The fire extinguisher for a Class C fire should be based on the amount of the Class A or Class B component. For extinguisher use on a Class D fire, the relative effectiveness is detailed on the extinguisher nameplate for the specific combustible metal fire for which it is suggested.

Placement

OSHA requires employers to select and distribute fire extinguishers based on the classes of anticipated workplace fires and also on the size and degree of the hazard, which would affect their use. The following chart contains the OSHA-specified maximum travel distances to an extinguisher by fire class.

| Fire Class | Travel Distance |

| Class A | 75 feet |

| Class B | 50 feet |

| Class C | Based on appropriate A or B Hazard |

| Class D | 75 feet |

According to the National Fire Protection Association’s NFPA 10 standard, the travel distance to a Class K fire extinguisher must not exceed 30 feet.

Training

Where the employer has provided fire extinguishers for employee use, the employer must provide an educational program to familiarize employees on the principles and use of the extinguishers. This educational program should be completed during the initial hiring and annually thereafter.

Maintenance, Inspection and Testing

Employers must inspect, maintain and test all portable fire extinguishers in accordance with 29 CFR 1910.157(e) and (f).

Visual Inspection: Portable fire extinguishers must be visually inspected monthly per 29 CFR 1910.157(e)(2). The inspection should assure that:

-

Fire extinguishers are in their assigned place

-

Fire extinguishers are not blocked or hidden

-

Fire extinguishers are mounted in accordance with NFPA 10

-

Pressure gauges show adequate pressure; carbon dioxide (CO2) extinguishers must be weighed to determine if leakage has occurred

-

Pin and seals are in place

-

Fire extinguishers show no visual sign of damage or abuse

-

Nozzles are free of blockage

Maintenance Requirements: The maintenance requirements depend on the type of portable fire extinguisher. Stored pressure or dry chemical type extinguishers do not require an internal examination. Water or steam type fire extinguishers should be discharged, disassembled and inspected annually (NFPA 10, 4-4.1.1). Dry chemical extinguishers that require a 12-year hydrostatic test are required to be emptied and subjected to applicable maintenance procedures every six years. Non-refillable, disposable dry chemical extinguishers are exempt from this requirement (29 CFR 1910.157(e)(4)). For additional fire extinguisher maintenance, follow the manufacturer’s suggested maintenance procedure.

Hydrostatic testing: Hydrostatic testing of portable fire extinguishers is done to help protect against unexpected in-service failure. This can be caused by internal corrosion, external corrosion and damage from abuse, etc. Hydrostatic testing must be performed by trained personnel with proper test equipment and facilities. OSHA requires hydrostatic testing according to the following schedule:

| Type of Extinguisher | Test Interval (Years) |

| Soda acid (stainless steel shell) | 5 |

| Cartridge operated water and/or antifreeze | 5 |

| Stored pressure water and/or antifreeze | 5 |

| Wetting agent | 5 |

| Foam (stainless steel shell) | 5 |

| Aqueous Film Forming Foam (AFFF) | 5 |

| Loaded stream | 5 |

| Dry chemical with stainless steel | 5 |

| Carbon dioxide | 5 |

| Dry chemical, stored pressure, with mild steel, brazed brass or aluminum shells | 12 |

| Dry chemical, cartridge or cylinder operated, with mild steel shells | 12 |

| Dry powder, cartridge or cylinder operated with mild steel shells | 12 |

For each extinguisher that is hydrostatically tested, the employer must keep a record that includes:

-

The name of the person or agency who performed the last hydrostatic test, and the test date

-

The signature of the person who performed the test

-

The serial number or other identifier of the fire extinguisher that was tested

This information should also be securely affixed to the tested extinguisher. These records must be kept until the extinguisher is hydrostatically re-tested or until the extinguisher is taken out of service, whichever comes first.

Commonly Asked Questions

Q:What is Halotron?

A:Halotron is a “Clean Agent” hydrochlorofluorocarbon (HCFC) discharged as a rapidly evaporating liquid that leaves no residue. It is intended for use in areas formerly protected by Halon portable extinguishers. Typical applications are in computer rooms, telecommunications facilities, cleanrooms, data storage areas and offices to help protect sensitive electronic equipment.

Q:What is a “recharge”?

A:A recharge is when a fire extinguisher needs to be refilled because it has been used or has lost pressure. You can tell if the unit needs to be recharged by the gauge on the fire extinguisher. On a fully charged fire extinguisher, the arrow should be pointing to 12 o’clock. If the gauge is in the red and says “recharge,” it can and needs to be recharged. If the gauge is in the red and reads “dispose of after use,” the fire extinguisher cannot be recharged and needs to be disposed of and a new fire extinguisher needs to be purchased.

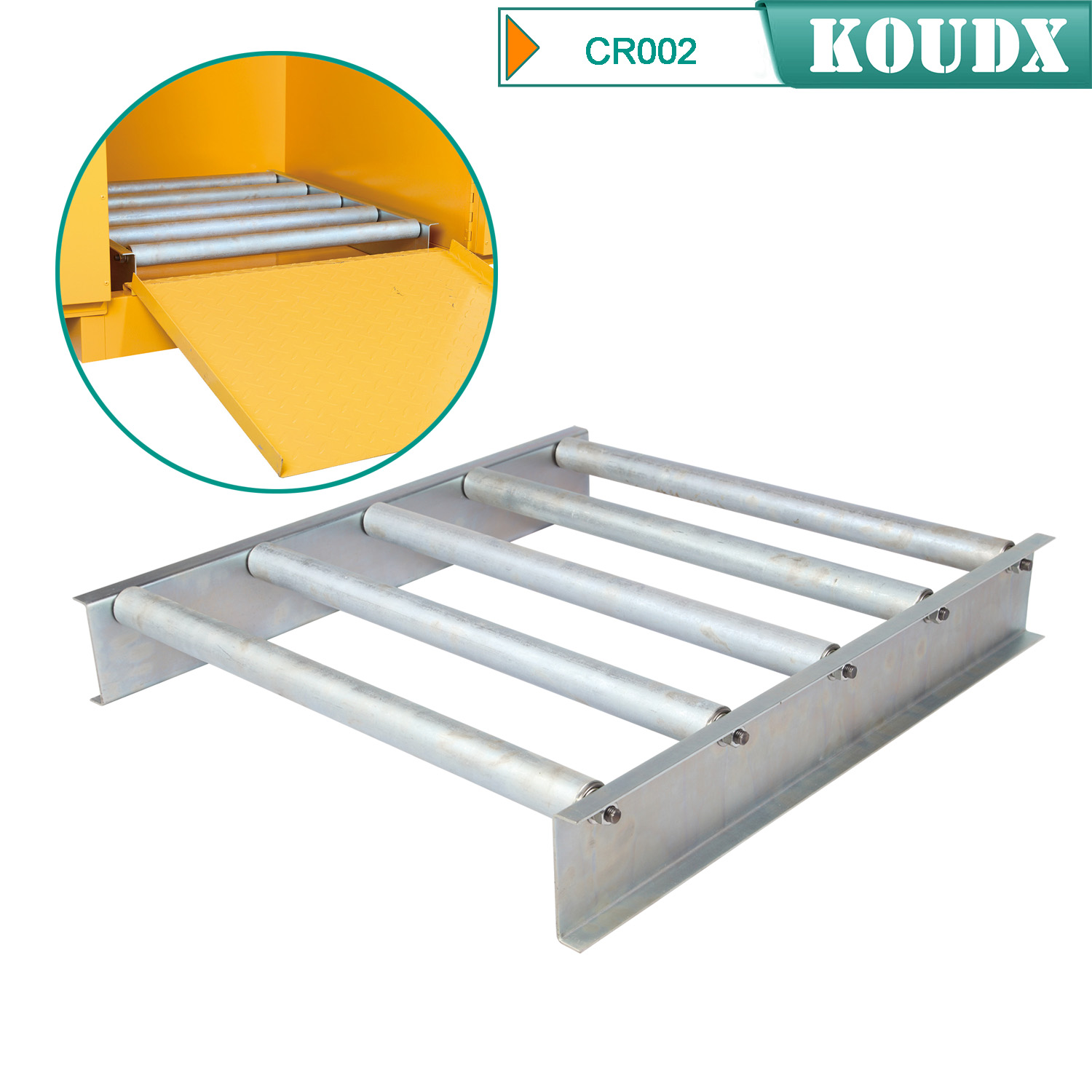

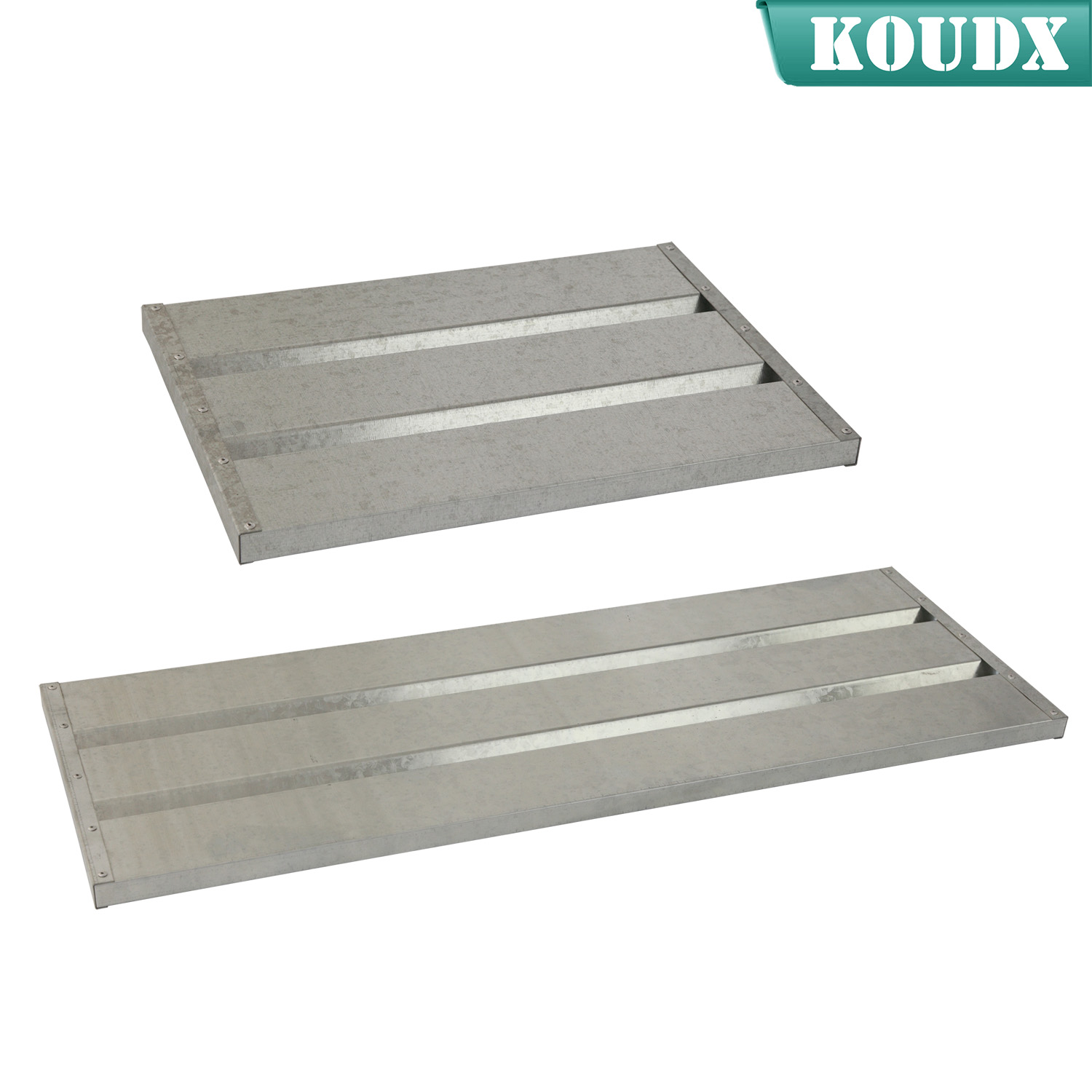

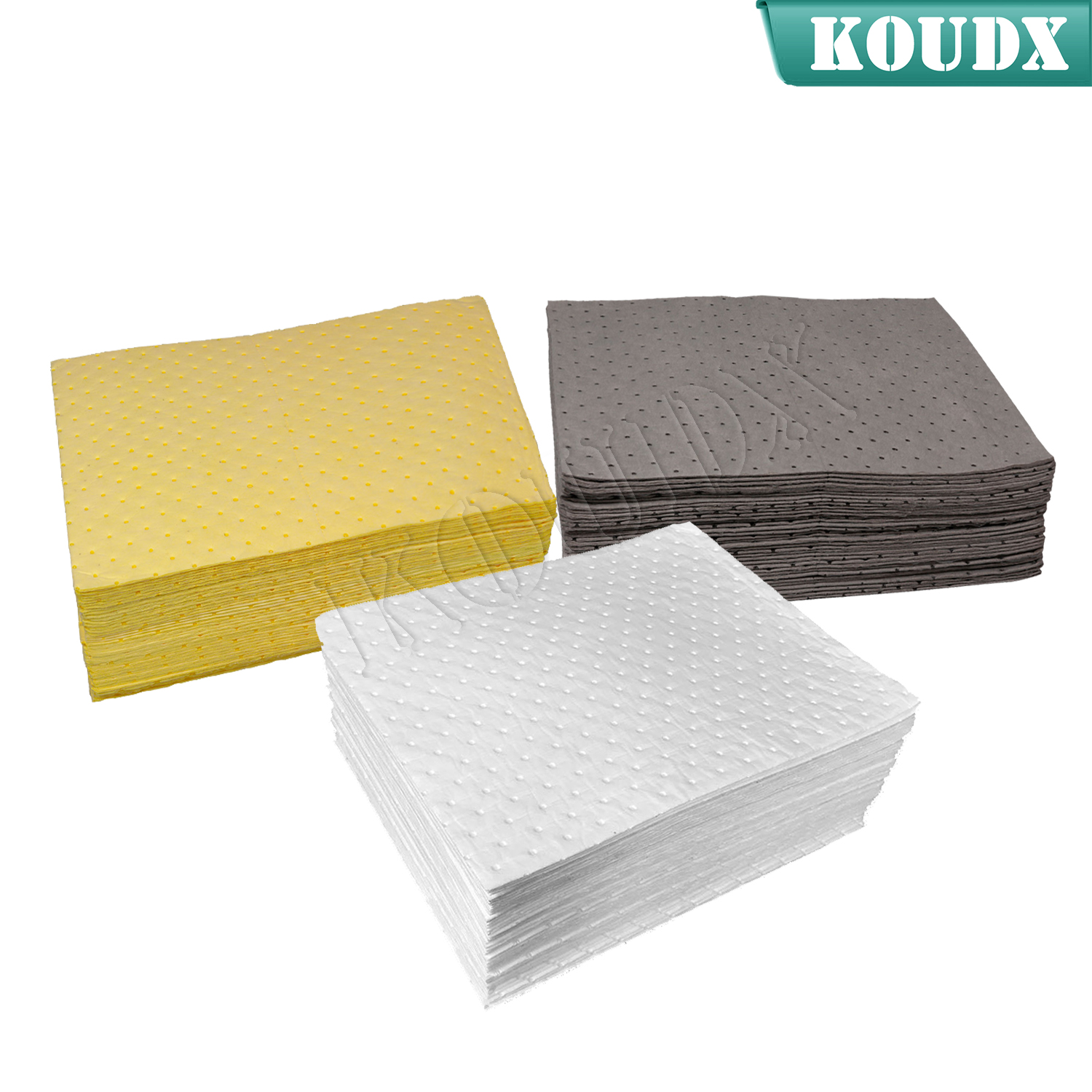

KOUDX(Shanghai Koudx Industry Technology Co., Ltd.) is a professional provider of industrial safety and environmental protection solutions. Based on the concept of market and customer demand, our fire safety cabinet was developed in accordance with the standards of OSHA 29 CER 1910.106 and NFPA CODE30. It is widely used in petrochemical industry, industrial manufacturing, university laboratories, food industry, automobile industry manufacturing, new energy and other industries.

We sincerely hope that in the journey of KOUDX's continuous development and expansion, we will be able to get the full support of our distributor partners in China and abroad, and have more long-term strategic partners, development together and achieve a win-win situation. Welcome to contact us (86) 400-168-8090, you can visit our website www.koudx.com for the detail information.