Reduce or eliminate chemical-related storage risks.

Chemicals play an important role in many workplace applications. The inherent hazards of chemicals can be reduced by minimizing the quantity of chemicals on hand. However, when chemicals must be in-house, proper storage and handling can reduce or eliminate some of the associated risks.

Proper storage information can be obtained from Section 7 of the Safety Data Sheet (SDS). As required by 29 Code of Federal Regulations (CFR) 1910.1200, an SDS must be on hand for every hazardous chemical in your workplace. Sections 7, 9, and 10 of the SDS can also answer questions such as:

-

Is the chemical a flammable?

-

Is the chemical a corrosive?

-

Does the chemical need to be stored other than at ambient temperature?

-

Is the chemical an oxidizer or reducer?

-

Is the chemical light sensitive?

-

Does the chemical require any special handling procedures?

Typical storage considerations may include temperature, ignition control, ventilation, segregation and identification. Proper segregation is necessary to prevent incompatible materials from inadvertently coming into contact. If incompatible materials were to come into contact, fire, explosion, violent reactions or toxic gases could result.

When segregating chemicals, acids should not be stored with bases, and oxidizers should not be stored with organic materials or reducing agents. Physical barriers and/or distance are effective for proper segregation.

If cabinets are used to segregate chemicals, consider the compatibility of the chemicals with the cabinet. For example, corrosives, like strong acids and caustics, will corrode most metal cabinets. Non-metallic or epoxy-painted cabinets are available and will provide a better service life with these types of chemicals. Some acids and bases may damage the epoxy-painted surfaces of a cabinet if a spill occurs. Also, perchloric acid should not be stored in a wooden cabinet.

There are cabinets designed specifically to store flammable liquids. It is important to be aware of the maximum allowable container size and maximum quantities for storage in cabinets based on the category of the flammable. The category of a flammable is determined by its flash point and boiling point. The Occupational Safety and Health Administration (OSHA) has defined a flammable liquid as any liquid having a flash point of not more than 93° C or 199.4° F (29CFR 1910.106(a)(19)). OSHA further classifies flammables into four categories. 29 CFR 1910.106(a)(19)(i-v) and Table B.6.1 of 29 CFR 1910.1200 Appendix B provides the criteria for the four flammable liquid categories:

| Category | Criteria |

|---|---|

| 1 | Flash point |

| 2 | Flash point 95 °F |

| 3 | Flash point > 73.4 °F and ≤ 140 °F |

| 4 | Flash point > 140 °F and ≤ 199.4 °F |

The following chart lists the maximum volume of flammables that can be stored in a single container type:

| Maximum Allowable Size of Containers and Portable Tanks | ||||

|---|---|---|---|---|

| Container Type | ||||

| Category 1 | Category 2 | Category 3 | Category 4 | |

| Glass or approved plastic | 1 pint | 1 quart | 1 gallon | 1 gallon |

| Metal (other than DOT drums) | 1 gallon | 5 gallons | 5 gallons | 5 gallons |

| Safety Cans | 2 gallons | 5 gallons | 5 gallons | 5 gallons |

| Metal Drums (DOT spec.) | 60 gallons | 60 gallons | 60 gallons | 60 gallons |

| Approved Portable Tanks | 660 gallons | 660 gallons | 660 gallons | 660 gallons |

The following chart lists the maximum volume of flammables that can be stored in a single flammable storage cabinet.

| Maximum Storage Quantities for Cabinets | |

|---|---|

| Liquid Class | Maximum Storage Capacity |

| Category 1 | 60 Gallons |

| Category 2 | 60 Gallons |

| Category 3 | 60 Gallons |

| Category 4 | 120 Gallons* |

*Not more than 60 gallons may be Category 1, 2, or 3 liquids. No more than 120 gallons of Category 4 liquids may be stored in a storage cabinet, according to OSHA 29 CFR 1910.106(d)(3)(i).

For ease of locating chemicals, many storerooms organize chemicals alphabetically. However, chemical storage based upon an alphabetical arrangement of chemicals may inadvertently locate incompatible materials in close proximity to one another. A few examples of this potentially dangerous storage method are demonstrated by the following pairs of incompatible materials:

| Chemical | Reaction |

|---|---|

| Acetic acid and acetaldehyde | Polymerization of acetaldehyde |

| Copper (II) sulfide and cadmium chlorate | Explosive reaction |

| Hydrogen peroxide and iron (II) sulfide | Reacts vigorously |

| Sodium nitrite and sodium thiosulfate | Explosive when heated |

Other common examples of incompatible chemicals:

| Chemical | Is Incompatible and Should Not Be Mixed or Stored With |

|---|---|

| Acetic acid | Chromic acid, nitric acid, hydroxyl compounds, ethylene glycol, perchloric acid, peroxides, permanganates |

| Acetylene | Chlorine, bromine, copper, fluorine, silver, mercury |

| Acetone | Concentrated nitric and sulfuric acid mixtures |

| Alkali and alkaline earth metals (such as powdered aluminum or magnesium, calcium, lithium, sodium, potassium) | Water, carbon tetrachloride or other chlorinated hydrocarbons, carbon dioxide, halogens |

| Ammonia (anhydrous) | Mercury, chlorine, calcium hypochlorite, iodine, bromine, hydrofluoric acid (anhydrous) |

| Ammonium nitrate | Acids, powdered metals, flammable liquids, chlorates, nitrates, sulfur, finely divided organic or combustible materials |

| Aniline | Nitric acid, hydrogen peroxide |

| Arsenical materials | Any reducing agent |

| Azides | Acids |

| Bromine | See Chlorine |

| Calcium oxide | Water |

| Carbon (activated) | Calcium hypochlorite, all oxidizing agents |

| Carbon tetrachloride | Sodium |

| Chlorates | Ammonium salts, acids, powdered metals, sulfur, finely divided organic or combustible materials |

| Chromic acid and chromium trioxide | Acetic acid, naphthalene, camphor, glycerol, alcohol, flammable liquids in general |

| Chlorine | Ammonia, acetylene, butadiene, butane, methane, propane (or other petroleum gases), hydrogen, sodium carbide, benzene, finely divided metals, turpentine |

| Chlorine dioxide | Ammonia, methane, phosphine, hydrogen sulfide |

| Copper | Acetylene, hydrogen peroxide |

| Cumene hydroperoxide | Acids (organic or inorganic) |

| Cyanides | Acids |

| Flammable liquids | Ammonium nitrate, chromic acid, hydrogen peroxide, nitric acid, sodium peroxide, halogens |

| Fluorine | Everything |

| Hydrocarbons (such as butane, propane, benzene) | Fluorine, chlorine, bromine, chromic acid, sodium peroxide |

| Hydrocyanic acid | Nitric acid, alkali |

| Hydrofluoric acid (anhydrous) | Ammonia (aqueous or anhydrous) |

| Hydrogen peroxide | Copper, chromium, iron, most metals or their salts, alcohols, acetone, organic materials, aniline, nitromethane, combustible materials |

| Hydrogen sulfide | Fuming nitric acid, oxidizing gases |

| Hypochlorites | Acids, activated carbon |

| Iodine | Acetylene, ammonia (aqueous or anhydrous), hydrogen |

| Mercury | Acetylene, fulminic acid, ammonia |

| Nitrates | Sulfuric acid |

| Nitric acid (concentrated) | Acetic acid, aniline, chromic acid, hydrocyanic acid, hydrogen sulfide, flammable liquids, flammable gases, copper, brass, any heavy metals |

| Nitrites | Acids |

| Nitroparaffins | Inorganic bases, amines |

| Oxalic acid | Silver, mercury |

| Oxygen | Oils, grease, hydrogen, flammable liquids, solids or gases |

| Perchloric acid | Acetic anhydride, bismuth and its alloys, alcohol, paper, wood, grease, oils |

| Peroxide, organic | Acids (organic or mineral), avoid friction, store cold |

| Phosphorus (white) | Air, oxygen, alkalis, reducing agents |

| Potassium | Carbon tetrachloride, carbon dioxide, water |

| Potassium chlorate | Sulfuric and other acids |

| Potassium perchlorate (see also chlorates) | Sulfuric and other acids |

| Potassium permanganate | Glycerol, ethylene glycol, benzaldehyde, sulfuric acid |

| Selenides | Reducing agents |

| Silver | Acetylene, oxalic acid, tartartic acid, ammonium compounds, fulminic acid |

| Sodium | Carbon tetrachloride, carbon dioxide, water |

| Sodium nitrate | Ammonium nitrate and other ammonium salts |

| Sodium peroxide | Ethyl or methyl alcohol, glacial acetic acid, acetic anhydrite, benzaldehyde, carbon disulfide, glycerin, ethylene glycol, ethyl acetate, methyl acetate, furfural |

| Sulfides | Acids |

| Sulfuric acid | Potassium chlorate, potassium perchlorate, potassium permanganate (similar compounds of light metals, such as sodium, lithium) |

| Tellurides | Reducing agents |

| General Incompatibilities by Chemical Groups | |

|---|---|

| Acids | Alkalines, Combustibles, Flammables, Cyanides, Nitrates and Reactive Sulfides |

| Oxidizers | Organics |

| Nitrates | Acids |

| Ammoniated Compounds | Hypochlorites / Bleach |

| Organics Nitrates | Perchlorates / Oxidizers / Metals |

In addition to chemical compatibility concerns, safe chemical handling requires regular inspections of chemical storage areas and maintenance of stringent inventory control.

Commonly Asked Questions

Q. What are some things to look for when inspecting a chemical storage area?

A. All chemicals should be properly labeled. Chemicals should have their caps secured at all times. No chemicals should be stored on bench tops, fume hoods, on the floor or extending into traffic aisles. Chemical shelves should not be over crowded. Chemicals should not be stored above eye level.

Q. What should we do if we have old, unlabeled chemicals in house?

A. Hire a hazardous waste contractor to come in and evaluate the situation and properly dispose of the materials.

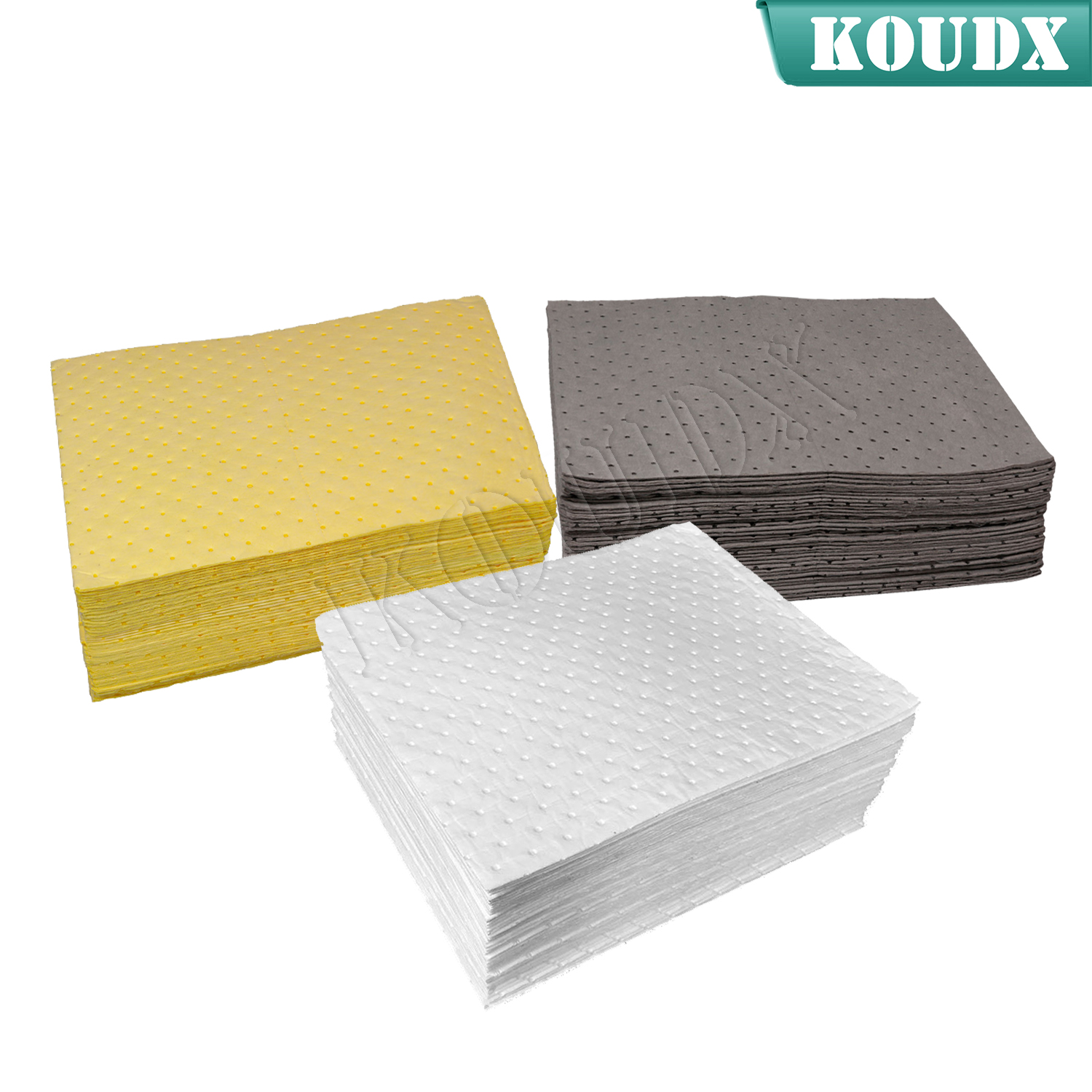

Q. What emergency equipment should be located near the chemical storage area?

A. First aid supplies, emergency phone numbers, eyewash and shower facilities, fire extinguishers, spill cleanup supplies and personal protective equipment should be readily available.

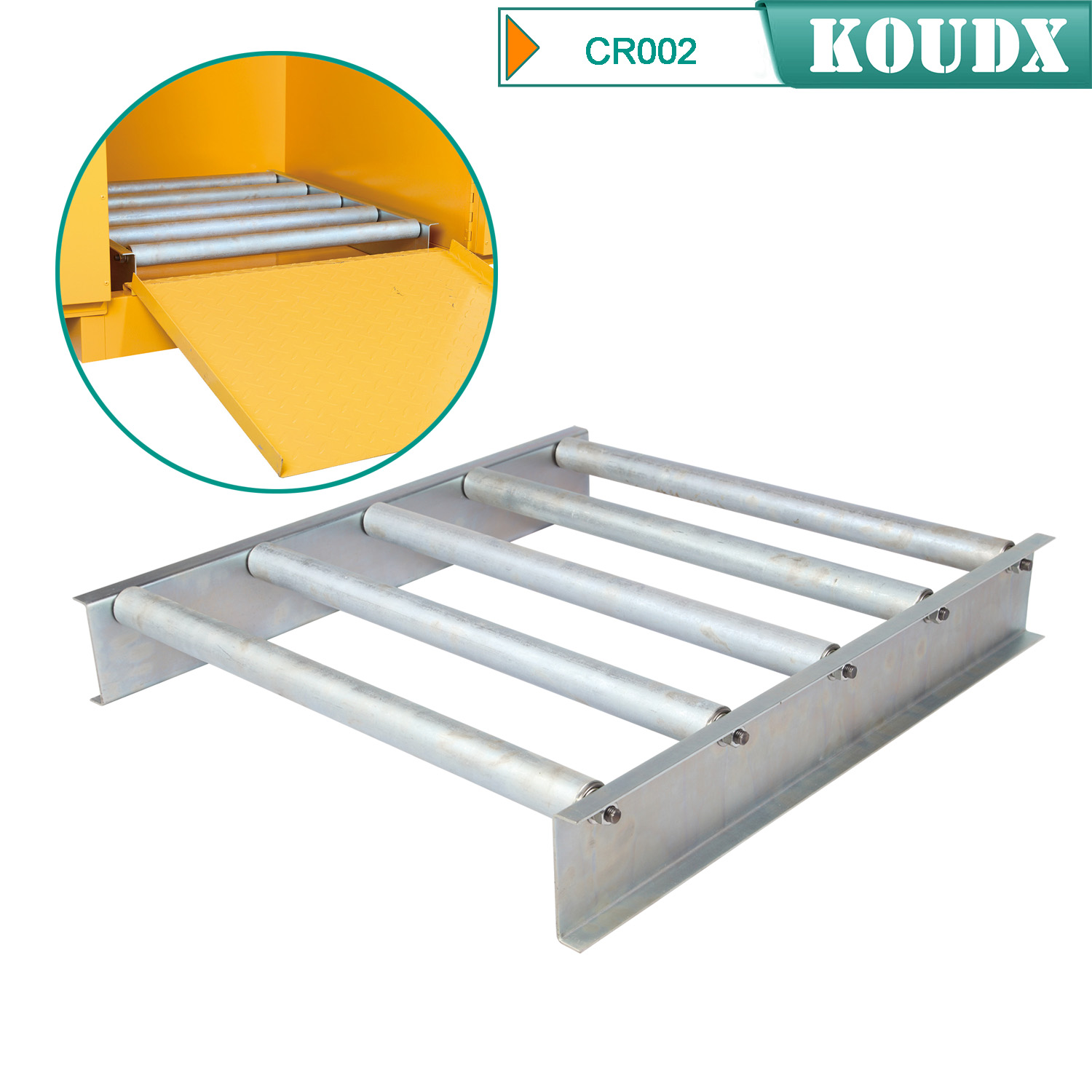

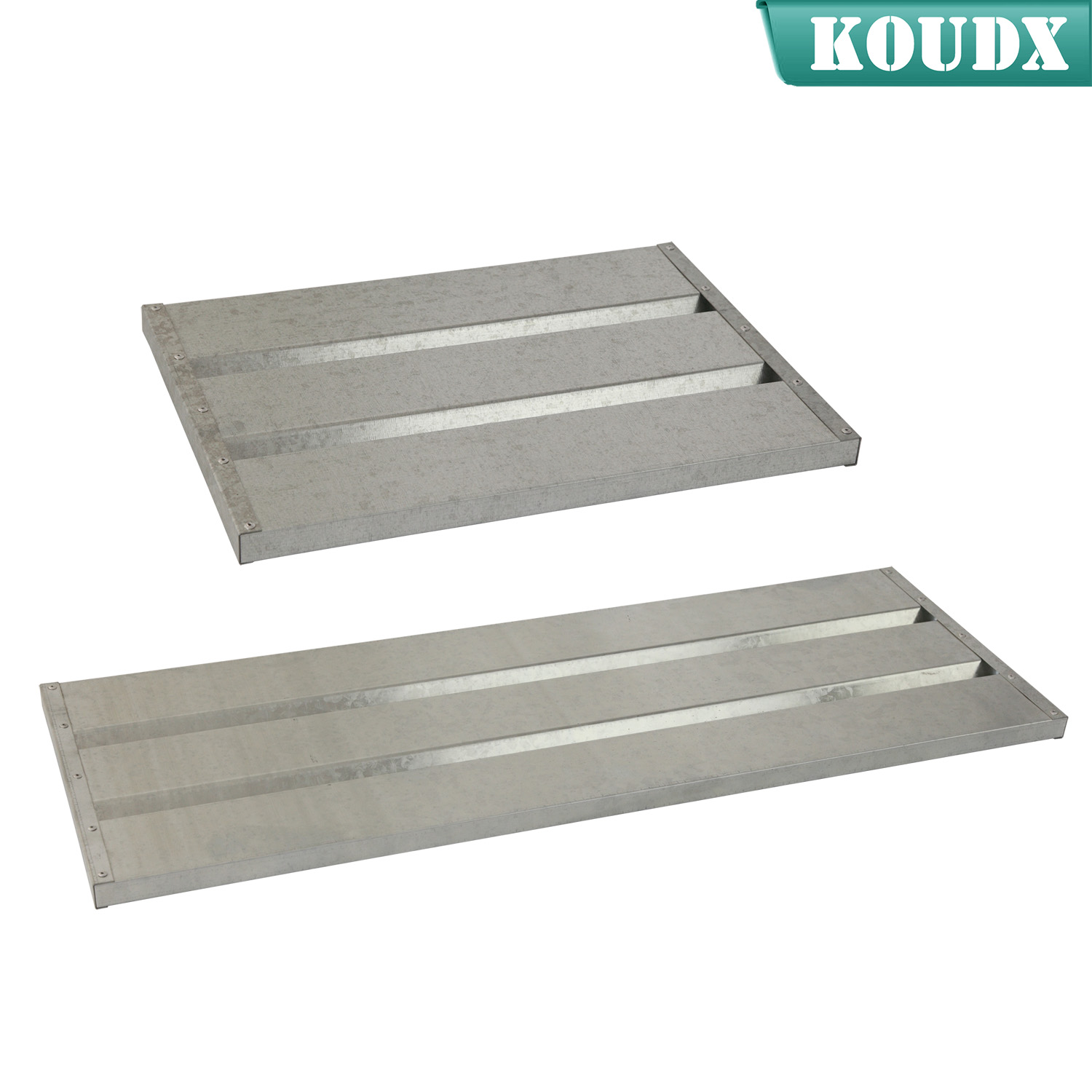

KOUDX(Shanghai Koudx Industry Technology Co., Ltd.) is a professional provider of industrial safety and environmental protection solutions. Based on the concept of market and customer demand, our fire safety cabinet was developed in accordance with the standards of OSHA 29 CER 1910.106 and NFPA CODE30. It is widely used in petrochemical industry, industrial manufacturing, university laboratories, food industry, automobile industry manufacturing, new energy and other industries.

We sincerely hope that in the journey of KOUDX's continuous development and expansion, we will be able to get the full support of our distributor partners in China and abroad, and have more long-term strategic partners, development together and achieve a win-win situation. Welcome to contact us (86) 400-168-8090, you can visit our website www.koudx.com for the detail information.