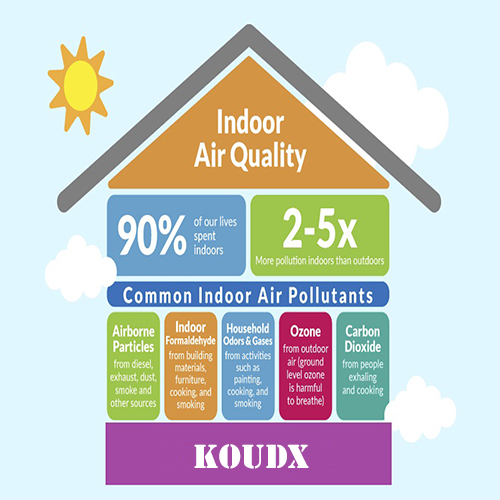

Learn how you can help improve your air and protect your employees.

Indoor air quality (IAQ) refers to the quality of air in non-industrial environments, such as offices, schools and other such workplaces. Since the energy crisis of the mid-1970s, indoor air quality has become an increasingly important issue for building owners, managers and occupants.

Although the Occupational Safety and Health Administration (OSHA) does not have IAQ standards, it does have ventilation and air contaminant standards. OSHA has identified the key attributes that typically lead to IAQ complaints as:

Improperly operated and maintained heating, ventilation and air-conditioning (HVAC) systems

Overcrowding

Radon

Moisture incursion and dampness

Presence of outside air pollutants

Presence of internally generated contaminates

Common Pollutants

Biological

Typically these pollutants are present where water is found. Water supports the growth of bacteria, viruses and fungi. Common biological pollutants can be dust mites, animal dander, legionella and pollen. Inadequate maintenance and housekeeping of building ventilation systems can compound the issue.

Chemical

Sources of chemical pollutants (gases and vapors) come from five main categories: products used in the building, products that can get pulled into the HVAC system from outside the building, accidental spills, products used during construction activities, and byproducts of combustion such as carbon monoxide, formaldehyde and nitrogen dioxide. Some of the most common indoor air pollutants and means to control exposure are discussed in Appendix A of OSHA’s “Indoor Air Quality in Commercial and Institutional Buildings.” OSHA document 3430-04 2011.

Particle

These are described as a solid or liquid, non-biological that can be suspended in air creating a respiratory hazard. This most often is dirt and dust drawn into the building ventilation system. Another source can be construction activities in the building resulting in suspended particles such as drywall dust, wood dust, and silica from cutting, drilling, or sanding of concrete. Common particles and control measures are also described in Appendix A of OSHA document 3430-04 2011.

Sources of Indoor Air Pollutants

There are many sources of air pollutants that contribute to IAQ problems. The importance of any one single source depends on several factors:

Quantity emitted

Toxicity of pollutant

Occupant proximity to the pollutant source

Ability of the building ventilation system to remove the pollutant

Sources of indoor air pollutants may include:

Building site or location

Building design

Building systems design and maintenance

Renovation activities

Local exhaust ventilation

Building construction materials

Building furnishings

Building maintenance

Occupant activities

Results of Poor Indoor Air Quality (IAQ)

Symptoms related to poor IAQ are varied depending on the type of contaminant. They can easily be mistaken for symptoms of other illnesses. The usual clue is that people feel ill while inside the building, and the symptoms go away shortly after leaving the building. Symptoms like headaches, fatigue, trouble concentrating, and irritation of the eyes, nose, throat and lungs are typical. Also, some diseases have been linked to specific air contaminants or indoor environments, like asthma with damp indoor environments. Whenever excessive moisture is present within the workplace, bacteria, mold and fungi can grow and can lead to respiratory issues such as allergic reactions, asthma, coughing, wheezing, shortness of breath, sinus congestion, sneezing, nasal congestion and sinusitis. Asthma is both caused by and worsened by dampness in the building.

Building managers need to treat IAQ complaints seriously and deal with them promptly. These situations often are difficult to diagnose and solve. OSHA suggests that a proactive approach be taken to address IAQ concerns. Failure to respond expeditiously and effectively to IAQ concerns can quickly lead to more numerous or serious adverse health issues.

Control of IAQ Problems

OSHA recognizes the “Three Lines of Defense” as a way of thinking about and applying specific actions to reduce or eliminate potential exposures to identified hazards. This is a commonly used and understood practice within the safety community. In this philosophy you always apply the most effective method first, working down from there. This begins with eliminating/engineering the hazards out, then implementing administrative controls such as policies and procedures, and lastly if the first two lines of defense are not feasible or insufficient, incorporating the use of personal protective equipment (PPE).

Eliminating/Engineering Controls

Eliminating the source of the pollutant should always be the first option and this starts with source management. This would include removal, substitution, and enclosure of pollutant sources. This is considered the most effective method when applied in a practical manner. For example, look for products such as paints and carpets labeled as “low VOC emitters” to help prevent IAQ issues at the source.

If the pollutant source cannot be eliminated then engineering controls are the next step to control exposure. Examples include: local exhaust systems, general dilution ventilation levels as suggested by National Institute for Occupational Safety and Health (NIOSH) and American Society of Heating Refrigerating and Air-Conditioning Engineers (ASHRAE) consensus standards, and air cleaning.

Administrative Controls

If elimination/engineering controls prove to be infeasible, administrative controls should then be considered. Administrative controls fall into three general areas: work schedules, training and housekeeping.

Personal Protective Equipment (PPE)

If elimination/engineering and administrative controls prove to be infeasible or insufficient, PPE should then be used to control exposure to indoor pollutants by use of respirators, gloves, protective clothing, eyewear and footwear where necessary.

Air Monitoring

Indoor air quality problems are difficult to diagnose and solve because of the large number and many types of common pollutants that can cause problems. The cumulative effect of chemical, biological and particle stressors is often the most difficult to identify. An IAQ investigation begins with thorough research and investigation at the problem site to identify potential pollutants. No monitoring should be done until these items have been identified.

If air monitoring is necessary, comparative samples from non-problem areas of the building are a useful tool in determining what the possible contaminants are.

The following is a brief list of common pollutants and the types of equipment used to identify each one:

| Contaminant/Stressor | Monitoring Equipment |

|---|---|

| Air speed | Anemometer |

| Lighting | Light meter |

| Heat | Thermometer |

| Noise | Sound level meter |

| Humidity | Hygrometer and moisture meters |

| Bacteria, virus, mold | Andersen air sampler |

| Volatile organic compounds | Photo ionization detector (PID), sampling pump and collection media, dosimeter badges and colorimetric tubes, specific colorimetric tubes |

| Carbon dioxide | Colorimetric detector tubes, electronic monitors |

Note: This is not intended to be a complete list of contaminants. ASHRAE 62.1-2016 lists common contaminant levels for these and other specific chemicals.

Standards and Regulations

Enforcement

OSHA

As stated previously OSHA does not have a formal IAQ standard, but it does enforce IAQ issues that pose a recognized hazard via the OSH Act General Duty Clause Section 5(a)(1).

National Consensus Standards

These standards provide guidance from their originating organizations.

ASHRAE:

62.1-2016 - Ventilation for acceptable indoor air quality. Specifies minimum ventilation rates and indoor air quality needed to avoid adverse health effects to human occupants.

55-2013 - Thermal environmental conditions for human occupancy. Specifies the combinations of indoor thermal environmental factors and personal factors that will produce thermal environmental conditions acceptable to a majority of the occupants.

ASTM:

E1971-05(2011) - Standard guide for stewardship for the cleaning of commercial and institutional buildings. The focus of this guide is to address appropriate cleaning activities and processes, to promote eco-efficiency and sustainability, and to avoid adverse impacts on the building occupants, cleaning personnel, the building structure itself, and the environment.

Frequently Asked Questions

Q: Is there any specific information that I should keep track of to identify IAQ problems?

A:The following information may be helpful to collect to aid in identifying if an IAQ issue is present:

Document the symptoms that just occur at work and go away when at home.

Are the symptoms related to a certain time of day, a certain season or certain location at work?

Did the symptoms start when something new happened at work, such as renovation or construction project or new chemical introduced?

Are there other people at work with similar complaints?

Prior history of similar symptoms? Any prior diagnosis?

Q: Has OSHA established specific exposure limits for contaminants found in non-industrial environments?

A: The current permissible exposure limits are used for industrial and non-industrial environments.

KOUDX(Shanghai Koudx Industry Technology Co., Ltd.) is a professional provider of industrial safety and environmental protection solutions. Based on the concept of market and customer demand, our fire safety cabinet was developed in accordance with the standards of OSHA 29 CER 1910.106 and NFPA CODE30. It is widely used in petrochemical industry, industrial manufacturing, university laboratories, food industry, automobile industry manufacturing, new energy and other industries.

We sincerely hope that in the journey of KOUDX's continuous development and expansion, we will be able to get the full support of our distributor partners in China and abroad, and have more long-term strategic partners, development together and achieve a win-win situation. Welcome to contact us (86) 400-168-8090, you can visit our website www.koudx.com for the detail information.