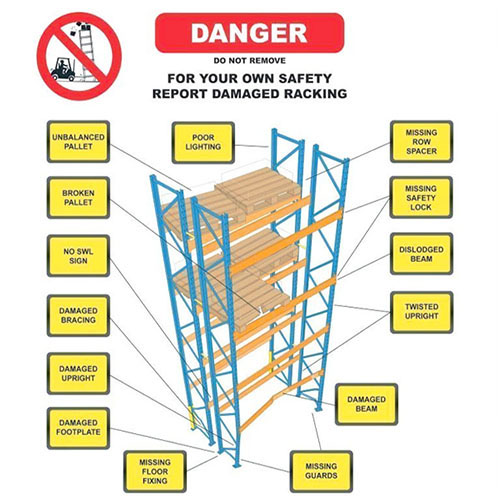

If your facility has pallet racking systems and mechanical handling equipment in use, the risk of damage to one or more components of the pallet raking system is very high. Pallet rack systems are designed for high performance and to support product loads many times their weight. The systems are built to standards that ensure they perform within designed load applications corresponding to the configuration for many years. However, the design specifications and safety factors issued by the pallet racking manufacturer typically do not take into account the loss of capacity and integrity once the pallet racking system has been damaged. Nothing affects the integrity of a pallet rack system like a forklift impact. Operators are not likely to report a collision involving pallet racking structures, so the damage can go undetected. This emphasizes the importance that pallet rack systems be routinely inspected and maintained to manufacturer and standard specifications to maintain original designed capacity.

Industry Standards

American National Standards Institute (ANSI)

ANSI MH16.1: 2012-Specification for the Design, Testing and Utilization of Industrial Steel Storage Racks is the industry voluntary consensus standard for industrial pallet rack systems. This standard applies to all industrial pallet rack systems, movable shelf racks, and stacker racks made of cold-formed or hot-rolled steel structural members. It does not apply to other types of racks, such as drive-in or drive-through racks, cantilever racks, portable racks or racks made of material other than steel. The ANSIMH16.1 has recently been incorporated into the more general International Building Code (IBC). The IBC includes the requirements and governs the construction of all warehouses in the United States. IBC standards must be met in order to obtain local municipal building permit approval during construction and upon final completion. As it relates to inspection and maintenance ANSI MH16.1 states:

-

1.4.1 Owner Maintenance: The racking system operator is responsible for maintenance and repair of the storage systems

-

1.4.9 Rack Damage: Upon visible damage, the pertinent portions of the rack shall be unloaded immediately and removed from service by the user until the damaged portion is repaired or replaced

Occupational Safety and Health Administration (OSHA)

OSHA Construction standard 1926.250(a)(1): All materials in tiers shall be stacked, racked, blocked or otherwise secured to prevent sliding, falling or collapse.

OSHA General Industry standard 1910.176(b): Materials shall not create a hazard.

OSHA General Duty Clause Section 5(a)(1): Employers are required to provide their employees with a place of employment that is free from recognizable hazards that are causing or likely to cause death or serious harm to employees.

Pallet Rack Inspections

The employer should establish and implement a program of regularly scheduled storage rack system inspections. The inspections should be performed by a qualified person familiar with the storage rack design and installation requirements retained or employed by the storage rack system owner. OSHA defines a qualified person in 29 CFR 1910.21(b): a person who, by possession of a recognized degree, certificate, or professional standing, or who by extensive knowledge, training, and experience has successfully demonstrated the ability to solve or resolve problems relating to the subject matter, the work, or the project.

Storage racks should be inspected periodically to check for any damage or abuse and immediately after any event that occurs that may result in damage to the rack. The frequency of inspections is up to the discretion of the owner and dependent on the conditions of use. At a minimum, inspections should be performed annually. The inspection schedule and results of the inspection should be documented and retained.

Even if you hire a professional inspector, it is suggested to designate and train someone within the company who will make periodic self-checks of the pallet raking systems. The Rack Manufacturers Institute (RMI) has many resources for inspectors and training curriculum.

What to Inspect

Generally there are four conditions to inspect pallet racking systems for:

-

Plumb and straight

-

Visible rust or corrosion

-

Load capacity

-

Damage

Plumb and straight

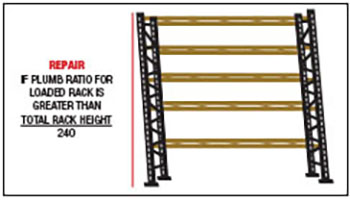

According to ANSI MH16.1-2012, the maximum top to bottom out of plumb ratio for a loaded rack is Total Rack Height/240 inches (see image 1). For example, a 15 foot (180 inches) column upright height maximum plumb ratio would be 180/240 or ¾ of a foot. This is measured from the centerline of the column upright at the floor to the centerline of the column upright at the top of the shelf elevation.

Visible rust or corrosion

Any rust or corrosion can indicate weakening metal. If paint is scraped, a rack may have suffered a collision and should be checked for plumbness and straightness of the upright columns.

Load capacity

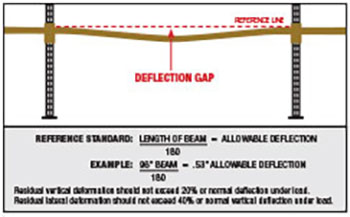

Each manufacturer publishes frame capacity charts. Applicable information should be prominently displayed on a placard at the end of each aisle. Never change original configuration or weight load without engineering approval. If an approved modification is made, remember to change the placards to reflect the new pallet racking specifications. Overloading can lead to beam deflection. The maximum allowable deflection is Length of the Beam/180 inches (ANSI MH16.1-2012). Beams should be inspected for deflection gap (see image 2):

Damage

Damage to specific components of a pallet racking system is the most common and serious problem that can affect the integrity of the racking system. Most common components involved in damage are beams, upright columns and foot plate/anchors.

-

Beams: Any beam with visible deformation or cracking of the beam end connectors should be unloaded and replaced. Be sure beams are fully engaged and installed with proper safety locks.

-

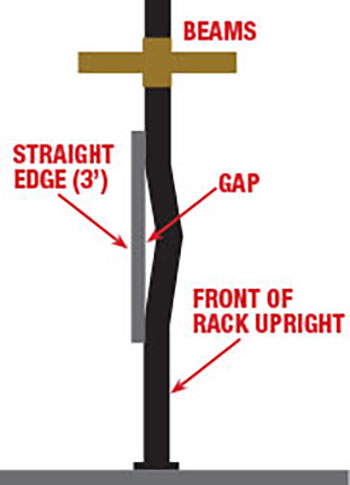

Upright columns: Any rips, tears beyond the manufacturer limits need to be repaired or replaced. Any deflection gap greater than ½ inch (ANSI MH16.1-2012) in either the down aisle or front to back direction must be repaired or replaced. This also includes horizontal and diagonal struts. See image 3.

-

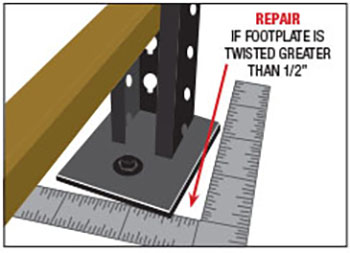

Foot plate/anchors: Any front and back footplates which are torn, ripped or twisted past ½ inch square. See image 4 below. Each footplate of the upright (front and back) must be anchored to the floor. Check for missing, loose or sheered anchors.

Note: A trick to measure for damage to upright columns is to place a steel straight edge (ruler or level) on the surface of the concave side of a damaged upright column segment. The straight edge should be centered on the damaged section’s length as accurately as possible. This will allow for a more accurate measure of the gap distance.

Just doing inspections isn’t enough. All inspections and actions taken to correct issues should be documented. Documentation helps track the process in the event of any future issues. This applies to all contracted inspection services as well.

KOUDX(Shanghai Koudx Industry Technology Co., Ltd.) is a professional provider of industrial safety and environmental protection solutions. Based on the concept of market and customer demand, our fire safety cabinet was developed in accordance with the standards of OSHA 29 CER 1910.106 and NFPA CODE30. It is widely used in petrochemical industry, industrial manufacturing, university laboratories, food industry, automobile industry manufacturing, new energy and other industries.

We sincerely hope that in the journey of KOUDX's continuous development and expansion, we will be able to get the full support of our distributor partners in China and abroad, and have more long-term strategic partners, development together and achieve a win-win situation. Welcome to contact us (86) 400-168-8090, you can visit our website www.koudx.com for the detail information.